Jim Clohessy has made the mistakes when it comes to making jig heads. Making your own heads is a straightforward project that has benefits in time, money and experimentation. The low down begins here...

When you start out in the soft lure fishing game it is easy to get somewhat disillusioned and many even give up due to tackle loss. In the early days I suffered badly. Every time I took to the water I was losing an amount of heads. I decided that I would start to make my own heads. My motivation here was twofold. Firstly I felt that it would hurt less to lose heads that I had made myself. Secondly I had a thing for articulated jig heads and was unable to get a supply in Ireland or the UK. In fact, it can be difficult to locate jig heads full stop. Many shop do not hold a large range of well priced heads.

It was while visiting the excellent angling show in Nantes that I found my answer. “Standard” jig head moulds are freely available online. Articulated heads are not. While wandering around the show I came across the stand of a French lure fanatic – Bricoleurre. Certainly Bricoleurre were the first company I had come across that could supply all the materials needed to mould your own soft lures. As well as soft lures they also have a superb range of moulds for leadhhead moulding including the “tete articulee” – the articulated jig head.

So before we get down to the nitty gritty let’s get the health and safety out of the way – Working with molten lead is dangerous. I would consider the moulded lead to be dangerous too. Make sure that you take adequate precautions before and during your work. Lead melting should be carried out in well ventilated areas. I only melt outside in the open air. Use gloves and make sure to wash and clean afterwards. Be safe!

In a recent piece we touched on some of the jig heads that are available: http://www.topfisher.eu/its-all-in-your-head/

This gives you an idea what anglers are using and might steer you towards some particular types. A standard ball jig head is the easiest to make and they are simple to use. As said earlier, I like to use articulated heads so I tend to lean towards that style. My first mould was the Bricoleurre 75015 Articulated mould: http://www.bricoleurre.com/index.php?main_page=index&cPath=41&zenid=40fba37e2020e6541799d4e1edb87a66

This mould makes heads from 25g to 75g, a decent spread for an angler that fishes both closer to the shore or in deeper water.

I checked out the Bricoleurre site recently and discovered that they had been reading my mind! They recently launched a range of moulds with a superb looking streamlined head in a huge range of sizes. Immediately I looked through the sizes to see what I needed to complement my existing heads. Firstly on the heavier side I wanted an 80g and 100g head. I find that in some deeper marks (130’+) I was struggling to hold bottom. The bigger heads would take care of this. Secondly I wanted a 25g head as an alternative to my usual and also an 18g that would be a lighter alternative for use while casting. I opted for the 18g/25g mould. These are numbered – 75072 for the lighter and 75075 for the heavier. I also opted to buy the 30/45g which has turned out to be my most popular head during the cod fishing months of the winter. that head is numbered 75073.

These heads are designed to accept hooks like a normal head. That is perfect and the easiest way to make heads. I use lots of “standard” heads. I don’t mind the standard head when the lure body is long. If the lure is short (120mm or shorter) then I refer the action got from an articulated head.

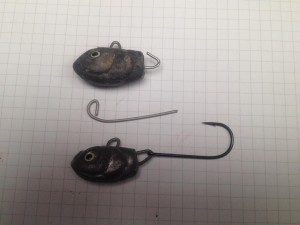

it is easy to make the “standard” heads into “articulated” heads by bending wire to suit rather than using a hook in the mould. If you look at the mechanics of all moulds you can do this with most.

Wire

When making articulated heads the wire you use is critical. The wire must be of a diameter that is strong enough yet it must be thin enough to fit through the eye of hooks around the size of 2/0 to 4/0. The wire cannot be brittle as it has to bend to suit the mould and also softer fitting the hook. I have done the experimentation and I have settled on two wires. I use a 1.2mm Piano Wire for the smaller heads and I use 1.6mm stainless welding wire for my bigger heads. The Piano wire is available from Bricoleurre and the 1.6mm I get from a local engineering shop.

The Process

The process begins with the forming of wire for the lures. I have experimented with different bends and have settled with the most simple bends that will suit the mould. You can see from the picture what the first part of the bend entails. It is important to check that you wire fits the mould and that you can close the two halves each time. The new moulds have a small bib to hold the lure built in to the mould. This little bib is not necessary for an articulated head. I place a little “blu tak” into the mould to fill this bib. The “blu tak” also holds the wire in place while you are closing and clamping the mould.

A decent wire cutters is a must. A “compound lever” cutter is better than any other. A very small bolt cutters works on the same principle. The result is easier snipping.

Once the wire is placed in the mould we are almost ready to pour. I like to warm the mould before the first pour. Even pour a little drop of lead into the empty mould. On the smaller heads I did drill out the inlet hole slightly more. I used a 4.8mm drill bit to widen the hole slightly as it was tending to block. Once drilled it has performed faultlessly.

The process becomes simple and repetitive. Fit the wire. Clamp the mould. Pour the lead. Split the mould. Remove the heads. Top up the lead pot if necessary. Fit the new wire. Clamp the mould and pour the lead. Once you are well organised you will turn out heads rapidly.

Once I am finished moulding I like to fettle the heads, that is clean off any edges from the moulding process. While the lead is fresh and shiny I will stick on some eyes. At that stage I will trim the wire and bend the hook holder most of the way over. You can paint you heads if you fancy. Some will create some stunning looking heads using powder paint. does painting make a difference? I’m not convinced but they certainly look good!

The only down side to painting is that the paint tends to wear off when the heads are stored loose in your tackle box. This tends to shed a fine dust into the compartment. But id you keep the minimum on the go you will have no problems.

At that stage these heads are ready for dressing and it is here that your imagination can run wild!

Of course you need to give some thought to your hooks. I have used various patterns and all work fine. Ideally a hook should have a fairly short shank. I cannot make up my mind which is better – a narrow or wide gape. A completely straight pattern is better than an offset one. Lately I have been using Kamasan B940s in 4/0. I have been using some Surecatch Techsharp Beak pattern hooks. They are very strong and long lasting but the eye is turned up and needs to be straightened to work properly. The Cox and Rawle Uptide Extra is a good articulated hook. Bricoleurre sell a specific articulated hook. I have used Chinu patterns to good effect once the point is not offset. You can also rig your articulated heads weedless.

If you are using “standard” hooks there are lots to choose from. I have been using Bricoleurres standard hook to good effect. You will find that most manufacturers will have a hook to suit. For example Mustad pattern 32833BLN is a good standard jig head hook.

You will find a mould to suit your needs whatever you preference. Making your own jig heads is a satisfying project. An articulated head allows you to experiment with different hook sizes and patterns. Many stick with standard built in hooks and are happy! Me? I think the Tete Articulee gives me an advantage at times and therefore I stick with it on most occasions. Whatever your choice the important thing is to take the plunge and get your mould and get making – It is easier than you think!